OUR PRODUCT

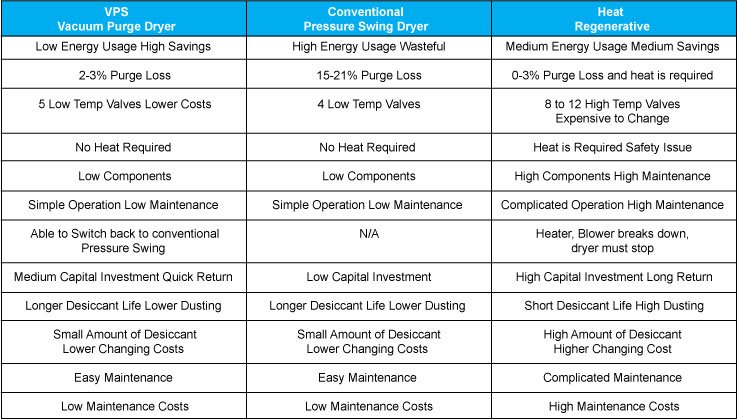

The VAPS VPS Vacuum Purge Heatless Pressure Swing Dryer for Compressed Air Dryer offers the lowest capital cost and lower long term operating costs compared to conventional heatless dryer and heat regenerative dryer. The VPS Vacuum Purge dryers offer the highest reliability solutions for low dew point compressed air.

These dryers are made simple to install, operate and able to provide consistent low pressure dew point of up to -40°C and -70°C

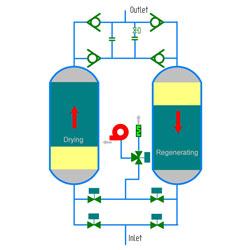

How the VPS Vacuum Purge Dryer work

Saturated compressed air enters the system through the Pre- Filter, where liquid water and oil contaminants are removed. The air then enters the dryer through the right chamber.

Moisture is adsorbed by the desiccant as the air flows through the chamber. Adsorption is an exothermic (heat releasing) process, and as it progresses through the chamber, heat of adsorption is released. This heat later contributes to regeneration. Dry compressed air exits at the outlet valve, and then through an After Filter, where any desiccant dust being carried by the air will be removed. The clean and dry air then

proceeds downstream to the plant.

While the right chamber is in the drying cycle, the off stream left chamber is depressurized to atmosphere. A portion of the -40°C/-70°C PDP dry air is metered through the purge adjusting valve, expanded to vacuum pressure (further reducing the dew point to -90°C or more), and is then passed through the wet desiccant bed counter-current to the drying flow. This extremely dry purge air, in conjunction with the heat of adsorption stored in the bed during the drying cycle, regenerates the desiccant

bed. The purge air is then exhausted through the purge exhaust valve and then a silencer to the atmosphere. Prior to switching, the newly regenerated left chamber is re-pressurized by closing the purge outlet valve

The dryer operates on a 4 to 10 minute automatic cycle, depending on the settings

5 minutes drying and 5 minutes regenerating.

The dryer's fail-safe design provides continued supply of dry air for

hours even if the control system's power supply is lost or interrupted.

|

|